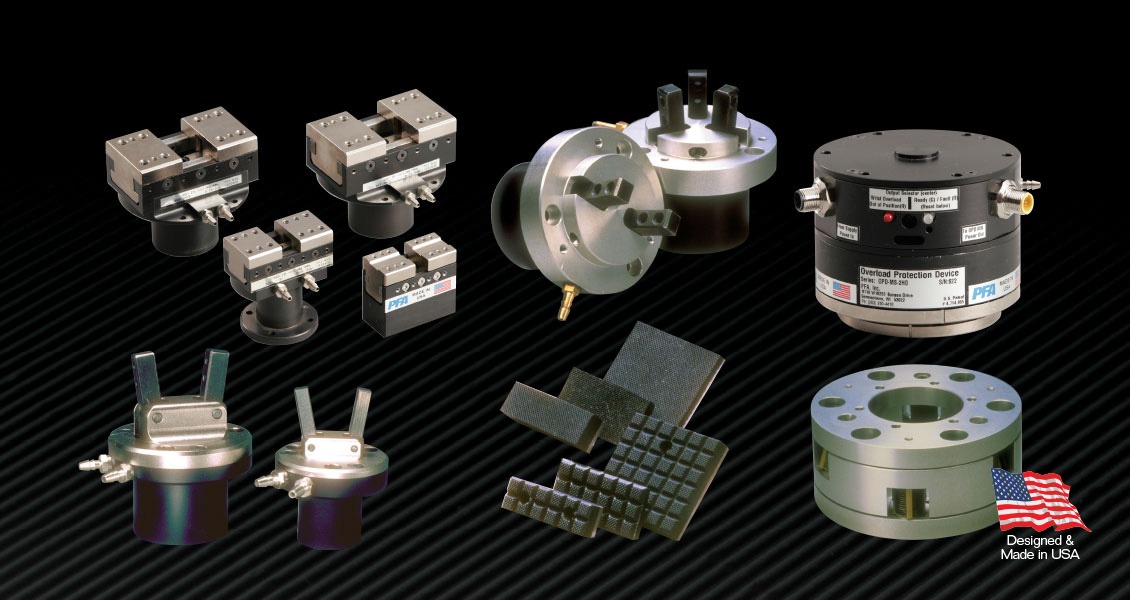

Modular End-of-Arm Automation

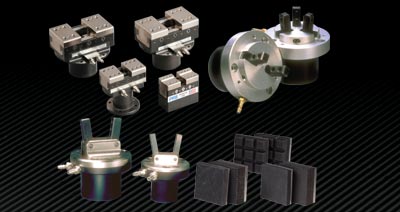

Robotic Grippers

Angular jaw grippers (GTP and DAG) and parallel jaw grippers (APG) are available in several sizes and single acting or double acting styles. Recessed mount options are available to nest up inside the Remote Center of Compliance (RCC) device for a compact gripping and insertion solution.

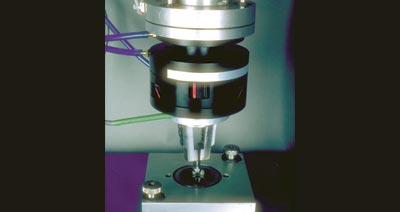

Compliance Devices

Remote Center of Compliance (RCC) devices correct for part-to-hole misalignment and reduce insertion forces in part handling applications. Also an excellent choice for non-robotic applications, where slight flex is helpful during part handling and placement. Wherever misalignment is present, an RCC can help.