If you are looking for a durable and efficient means of protecting your parts or products in pick and place, industrial clamping, work holding, or other industrial applications, you likely have heard about the great benefits associated with utilizing non-slip rubber gripping pads. As a highly customizable and easily replaced product, rubber gripper pads can accommodate a wide variety of uses. In this article, we will look at the benefits associated with using rubber gripper pads and a few examples of the nearly limitless possibilities.

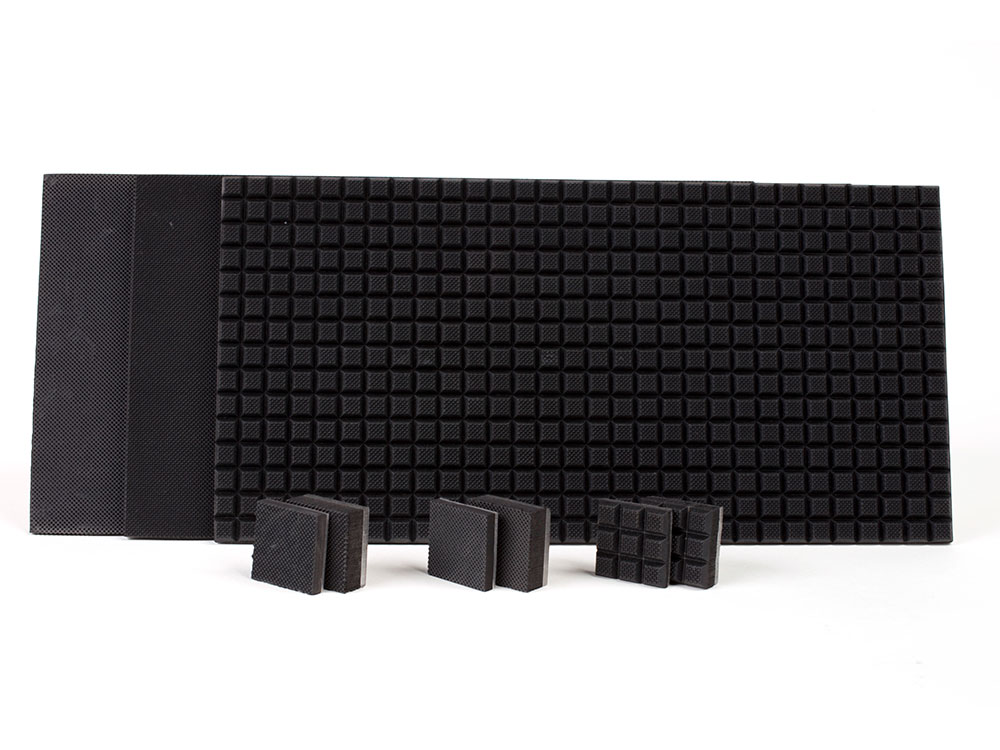

PFA Inc.’s rubber gripper pads come in three distinct surface designs to not only provide the needed protection for your products but also provide the maximum amount of friction, drainage, and flex (soft touch) for your unique applications. Most often, manufacturers will utilize rubber gripper pads to provide additional friction for applications in which grip force and finger friction are not sufficient enough to grab the part securely. The friction coefficient for steel to steel is estimated at .28, while adding a simple and replaceable gripper pad increases this by 70% – 85%.

For contoured parts such as test tubes or round shafts, the impact of a rubber gripper pad is even more significant. The compression of the rubber material at high points and flex of the gripper pad surface conforming to the part can greatly increase clamp force well beyond any frictional effects. When the rubber wraps around contours, the part cannot be removed without great effort. With rubber gripper pads clamp forces can often be reduced for improved part handling.

For ease of assembly, PFA manufactures rubber gripper pads with fully integrated steel and aluminum backing plates. Pads with included backplates are molded and cured during bonding to either steel or aluminum for a molecular level integration of rubber to metal. This provides the needed support that is critical for most applications benefiting from maximum performance and ease of replacement. Fastening the pad to tooling or fixtures by attaching through the backing plate provides a secure and dependable arrangement.

To maintain durability, PFA Inc. manufactures most rubber gripper pads to be resistant to oils and corrosive elements common to many heavy industrial manufacturing processes. Furthermore, the popular Nitrile Butadiene Rubber (NBR/Buna-N) elastomer is able to operate over a broad temperature range to remain reliable in demanding environments that require heated applications.

Other elastomer materials, such as Neoprene, are available on special order, if applications require special material properties and custom performance. Some of the other features and benefits provided by rubber pads include:

- Reliable Gripping for Parts

- Protection for Tooling, Jaws, and Parts

- Easy Modification for Customized Applications

- Compliant Surface Provides Softer Touch

- Increased Resistance in Harsh Environments

- Easy Installation and Replacement

- Adapts to Meet Custom Needs

As you can see, PFA rubber gripper pads meet a variety of needs faced by modern manufacturers that utilize robotic gripping or focus on pick and place, workholding or other general industrial applications. To order PFA Inc.’s rubber gripping pads online, we encourage you to visit the online store product page.