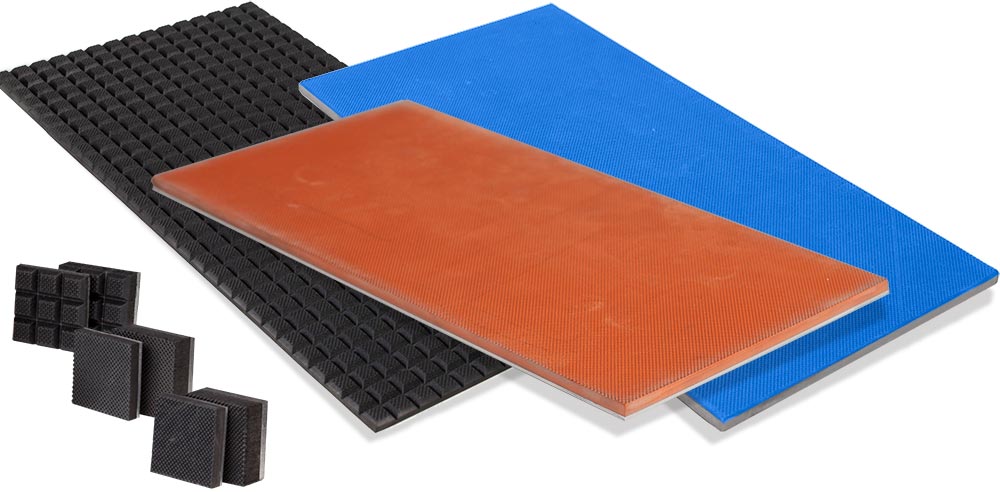

Durable, non-slip rubber pads for industrial and robotic applications provide strong gripping surfaces for grasping items using lower clamping forces, while also protecting parts during handling and assembly. The rubber elastomers, available in Buna-N, Neoprene, Silicone, and Viton® operate over a variety of broad temperature ranges and resist a variety of oils and corrosive elements. Pads with backplates are cure-bonded to aluminum, carbon steel, and stainless steel plate for a molecular level integration of rubber to metal, offering a bond stronger than the base rubber itself.

Metal backing provides stiffness and support to the rubber, allowing easy attachment to gripper jaws or other structures. Typically sections are attached to fingers or fixed structures using high strength adhesive tapes available from PFA or with standard fasteners after modification. Metal backed pads are easily machined to match custom applications, and holes may be drilled to provide quick attachment and removal.

Historically, Gripper pads have been available in 6” x 12” sheets of three surface styles bonded to Steel or Aluminum backing in only one material and durometer (Buna-N, 60 duro). Along with these standard pads, sheets are now available in smaller 1.2” x 1.2” sections and some other materials and durometers. Additional offerings are available by special order and may become available as standard products. Unique pad configurations and styles are also available as bulk material or as finished parts from customer provided drawings or specifications.