Vacuum grippers, also known as suction cup grippers, can be a simple yet highly effective gripping solution for a wide range of applications. With the right type of gripper in the right integration, vacuum grippers provide safe, powerful grips in collaborative robot (cobot) applications.

Using the difference between a vacuum and atmospheric pressure, vacuum grippers lift, hold, and move objects. The vacuum is created by a miniature electromechanical pump or compressed air-driven pump. To ensure a cobot can safely hold an object, the vacuum flow must not be interrupted.

Vacuum grippers come with added advantages such as the ability to handle a variety of item types and a lower price compared to other types of grippers. However, vacuum grippers come with added electricity costs to power compressed air or vacuum pumps. Additionally, vacuum grippers are sensitive to dusty conditions.

Each of the several types of vacuum grippers has its own advantages and disadvantages. Vacuum grippers commonly use either a compressed air-driven pump or a miniature electromechanical pump. Compressed air-driven grippers produce four to ten times more power than their electromechanical counterparts. Electromechanical vacuum grippers, however, excel in applications demanding a high degree of mobility.

While the compressed air-driven pump provides superior lifting capacity, it can also increase operating costs because of the electricity needed to run the compressor. Conversely, miniature electromechanical pumps shine in applications with a high degree of mobility; however, they often generate less power than compressed air-driven pumps.

Because vacuum grippers work best in applications when the vacuum flow is uninterrupted, vacuum grippers are ideal for parts that are large enough and flat enough to create enough difference in pressure between the vacuum and atmospheric pressure. This means parts with large, flat sides are ideal for vacuum grippers. However, excessively heavy parts may not be suitable since an enormous amount of negative pressure is needed for this. In cobot applications with light, flat parts, vacuum grippers are an effective gripping solution.

Because there are other types of grippers that rely on force to grip the inside or outside of parts, it can be difficult to know if a vacuum gripper is an optimal solution for your cobot. That is why it is important to compare your options with the needs of your application.

When choosing a gripper, it is important to be guided by the specific application you have in mind:

- What types of items will be handled?

- Will the gripper handle a single item or a mix?

- Will the gripper be utilized in a cleanroom environment?

- What is the shape of the items the gripper will handle – flat, curved, irregular, etc.?

- Do you need the gripper to provide data feedback?

- Does the gripper need certifications – food-safe, IP7, compatibility, etc.?

- Will the gripper operate in tight spaces?

Why Choose PFA for your Automation Solutions?

If your cobot application needs to be able to pick up, manipulate, and place products, then you are going to need a robotic gripper. PFA offers some of the highest force-to-weight ratio grippers to make your application a success. With so many types, sizes, and configurations on the market, it can be daunting when selecting the optimum gripper for your robot tool. Let us help you get a grip on your automation system by contacting us today or calling 262-250-4410.

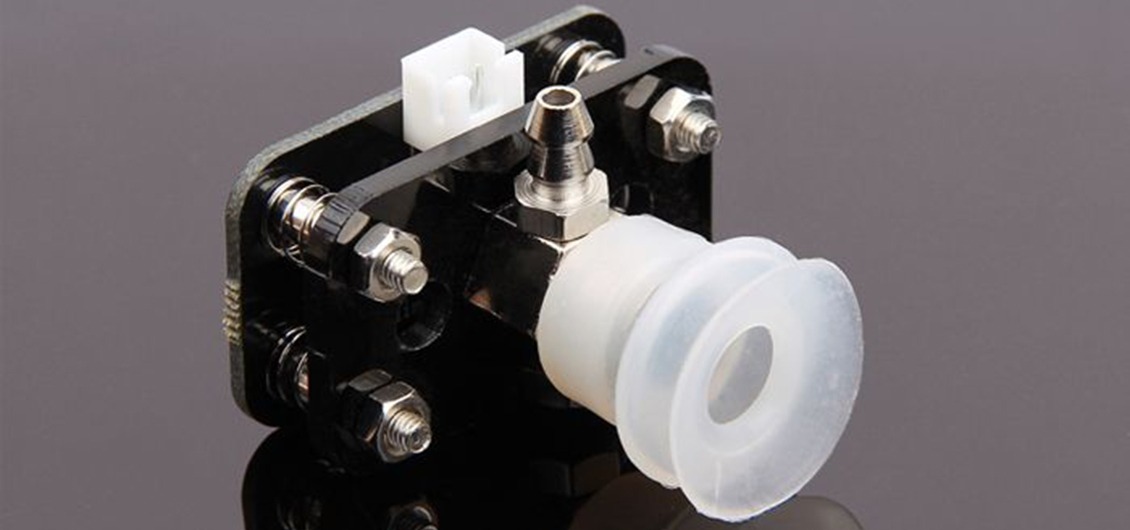

Photo taken from openhacks.com