Simplify Injection Mold Sensor Monitoring with SWITCHMAX

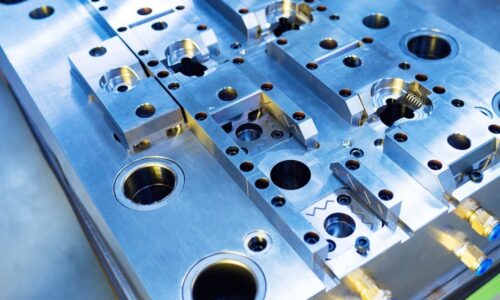

Injection molding is a complex process that requires precise monitoring of various parameters to ensure optimal performance and product quality. One crucial aspect is sensor monitoring, which enables the detection of specific equipment positions, ensuring the proper functioning of the injection molding machine. PFA, Inc. has developed an innovative solution called SWITCHMAX® – a plug-and-play […]