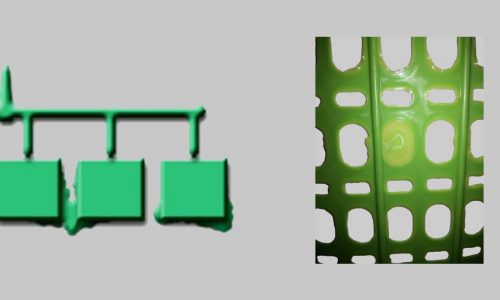

What Is an Injection Mold Slide?

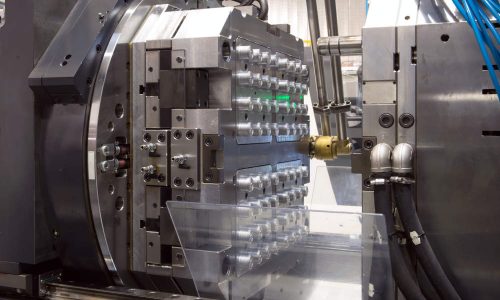

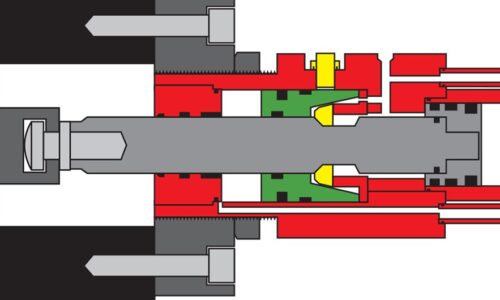

Since many injection molded products have special requirements, a mold side-action or slide is often used to form complex geometries and release the finished product upon mold opening. To achieve this, a “slide” or “slider” is often used as a core-pulling mechanism. At its most basic level, the slider is used to turn the vertical […]